What do you think about your private Internet of Things in the Public Cloud using RFID? Just check how easily you can use RFID and eTags technology in your business case to create your own IoT.

Imagine that everyday items at your home are simply connected to the internet of things network passively, without any battery or power supply. Yes, this is possible by using RFID technology - Radio Frequency Identification. Let’s check out use cases and how can we use this technology to boost our business.

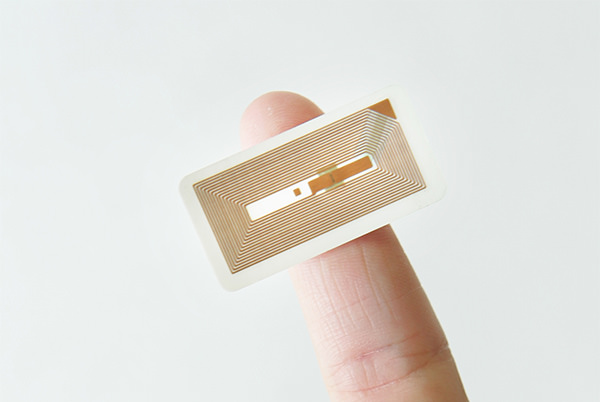

eTag

Use Cases

Vehicle Access Control & Tolling

Fast, economical, and highly secure: this is how vehicle identification, parking management, and access control systems need to be. Using eTags and UHF systems make this possible. In the process, they can be integrated into existing access solutions or used as stand-alone systems. Using proven technology, and combining software and hardware components we’ve prepared a complete solution dedicated to controlling vehicle access.

-

Vehicle identification. You know who is driving when the vehicle has an identification tag. The UHF windshield tag is identified up to 10 meters (33 ft). The tag does not contain a battery and is maintenance-free

-

Vehicle detection. In real-time readers inform systems about movement and vehicle detection. All activities are gathered and securely stored inside of the system

-

Vehicle access control. Managing permissions, new cars and access revoking is possible with a Cloud dashboard dedicated to organization or property administration

-

Vehicle access history. For audit purposes, all data is stored in the system to enable searching and tracing by specific vehicle or time period

Automatic Vehicle Identification is a highly reliable, secure, and cost-effective solution. Using a RFID system with secure labels allows to automatically identify vehicles for registration, toll collection, and access control in a seamless way.

Product tracking & Identification

Managing and locating important assets is a key challenge for almost any business. Time spent searching for critical equipment can lead to expensive delays or downtime, missed deadlines and customer commitments, and wasted labor. Companies have traditionally addressed this problem by managing assets using serial numbers and spreadsheets, or tracking equipment with barcode labels. However, both of these methods require a significant amount of manual labor. One way to quickly improve asset management is by utilizing radio frequency identification (RFID) technology to automatically track those assets. An RFID asset tracking system uses electromagnetic fields to transmit data from an RFID tag to a reader. Whether you are talking about office equipment in a multi-story building, wheelchairs and IV pumps in a large hospital, tools, and equipment in a factory or pumping equipment in far-flung oil fields, RFID can provide accurate, real-time tracking data for fixed and mobile assets.

-

Unique identification as RFID tag is programmed with a unique code to allow identification

-

Fast and paperless data collection to share online and supply chain assurance

-

Brand protection with unique eTags to ensure the authenticity of the product

-

Comply with legislation around the world

E-mobility

E-mobility is developing very intensively. With the help of RFID tags, it is already possible to authorize at the charging station, and the data stored in the tags are transferred to the central system. It is possible thanks to a special chip responsible for handling events handled at the charging station. All data goes to the cloud, creating the internet of things, where information about all charging stations, their load, parameters, etc. is stored.

-

Fast authorization - very safe authorization using RFID cards

-

Network of all devices, which are registered in IoT

-

Managing of charging stations from one dashboard

-

Special algorithms for charging handling

Autonomous Shops

Can you imagine entering a store where there is no seller? Where you can come in at any time of the day or night, whether it’s a holiday or not, and buy what you need. Would you also like to know how much you will pay for the purchases you have in your basket? It is possible now. The technology we use allows you to create a full automatic store, which, using RFID tags, allows you to implement a fully maintenance-free and fully secure sales process.

-

Autonomous shops open 24/7 compliant with legal art and regulations

-

Costs reduction and revenue maximization

-

Automatic stocktaking in real-time

-

Automatic ordering of missing products

RFID in commerce has a huge use. What has been done manually by employees so far can be done fully automatically, starting from inventory, sales, collection of receivables, ordering new deliveries, tracking sales trends of a given product, etc. This is done with full availability 24/7 without any downtime or interruptions.

Medicines

Did you know that all medicines, organs for transplantation, or vaccines must be stored at appropriate temperatures, sometimes even as low as -80 degrees Celsius and below? It is required to be used safely without endangering the recipient. So how can we say with 100% certainty that, for example, a vaccine has not been stored at temperatures other than intended, from its production to its use, including transport? This is possible thanks to eTags with RFID technology, which, placed on vaccines, allow you to read all the temperatures in which they were stored. Thanks to this, it is possible to identify and process many factors of storage and transport of a given product during one scanning of the entire batch.

-

Monitoring of physical environment parameters

-

Guarantee the originality of the product

-

Automatic identification of acceptability for use

-

Easy distribution of the product

This is a case of gaining an advantage and introducing new standards to the pharmaceutical market.

Luggage tracking

At airports around the world, passengers lose their luggage all the time. This is due to imperfections in technologies and processes that automate luggage handling. To rule it out it is enough to modernize the luggage handling process at airports so that each luggage is marked with an RFID eTag (sticker/tag), in which information about the destination airport will be saved, and then, using gates with RFID readers, their full automatic handling will take place, in which there is no room for human error. Each change of luggage location is saved in the central system, thanks to which it is possible to fully track the luggage.

-

Luggage tagging with RFID when checking in

-

Automatic identification of luggage location

-

Online luggage tracking

-

Prevention against loss of luggage

The use of RFID tags is a new dimension of handling both luggage and passengers at the airport. There is no need to handle boarding passes anymore, an eTag RFID is enough.

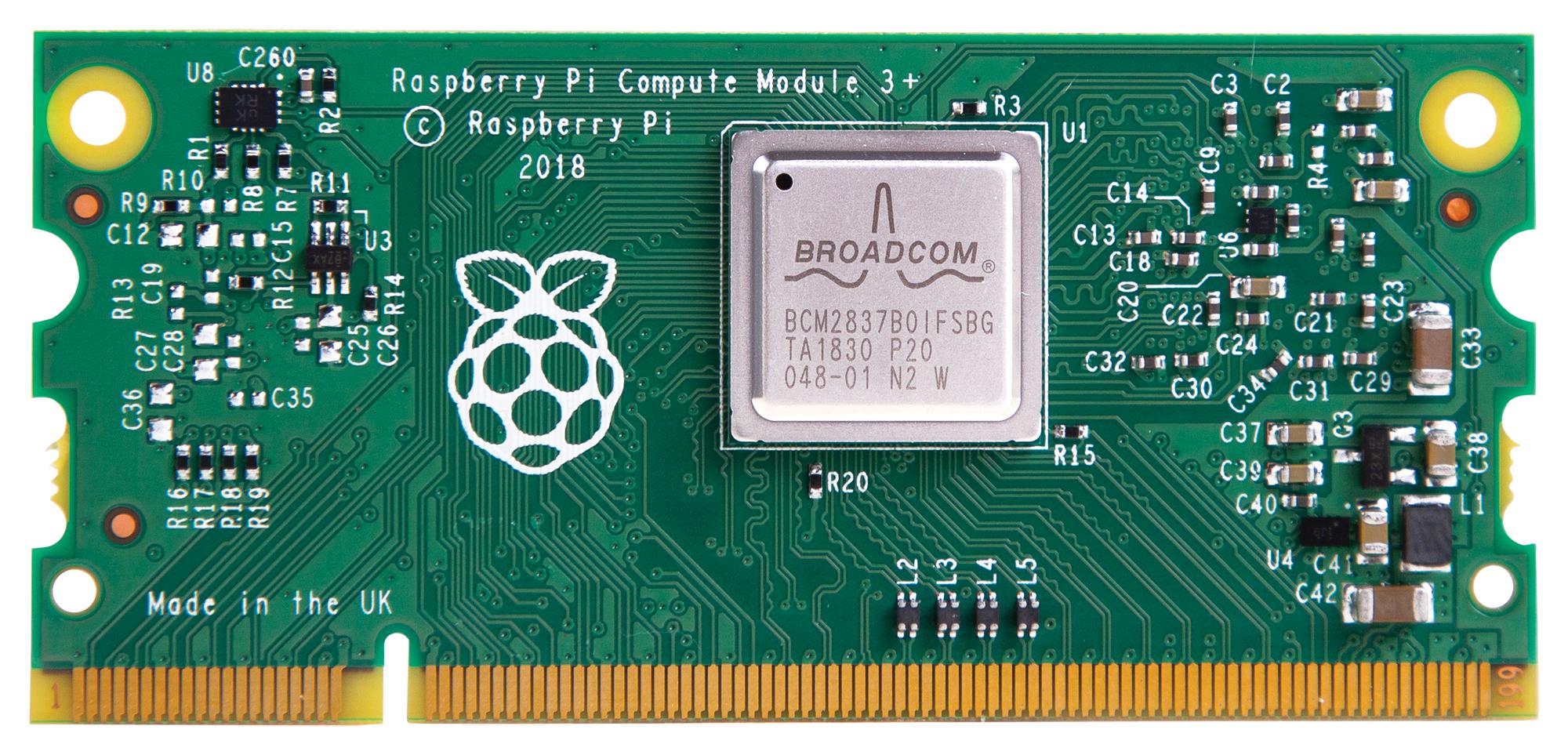

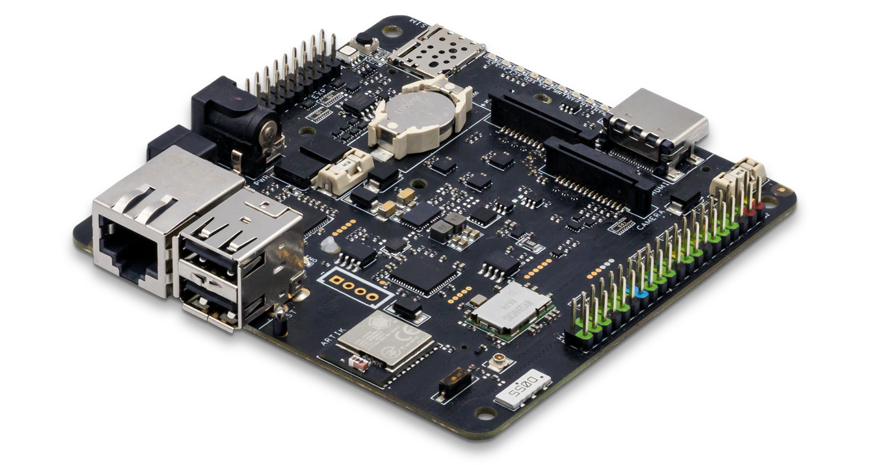

Equipment

When preparing hardware solutions we should begin with the three components.

-

Ultra High-Frequency Reader is used to gather information about eTags, their position, and status

-

eTags RFID are very small antennas attached to products or items which will be identified by UHF readers

-

Compute module process all information, synchronize with the Cloud application, and cooperate with external devices

-

Development board

On the market, we can find many development kits to test and deploy our solution locally.

Finally we will be able to set up eTags placed on different products with Cloud environment or third party devices which can be controlled by compute module. Our device will be a complete and ready-to-use electronic equipment dedicated to gathering all eTags signals, relaying information to the cloud, and cooperating with devices like engines or payment terminals. Using trusted standards like EPC Global Gen 2 Class 1 our equipment can be compatible with different types of eTags and can be integrated with third-party hardware devices to control and connect with them.

Communication

Connections between all components in IoT systems are wireless. eTags are scanned by readers to identify, authorize and track. Readers exchange information between eTags and Cloud centralized system with secured HTTPS protocols.

-

EPC Global Gen 2 Class 1 is used to communicate between eTags and UHF readers

-

GPRS, WiFi communication between devices and Cloud systems based on asynchronous events is a proven standard for IoT solutions

-

HTTPS, SSL secure connection between readers and Cloud is a guarantee of data confidentiality

-

Connection to control external devices is possible directly from the Hardware part or Cloud API level

Modularized and flexibly designed components are connected using global standards to make up a complete IoT product.

Software

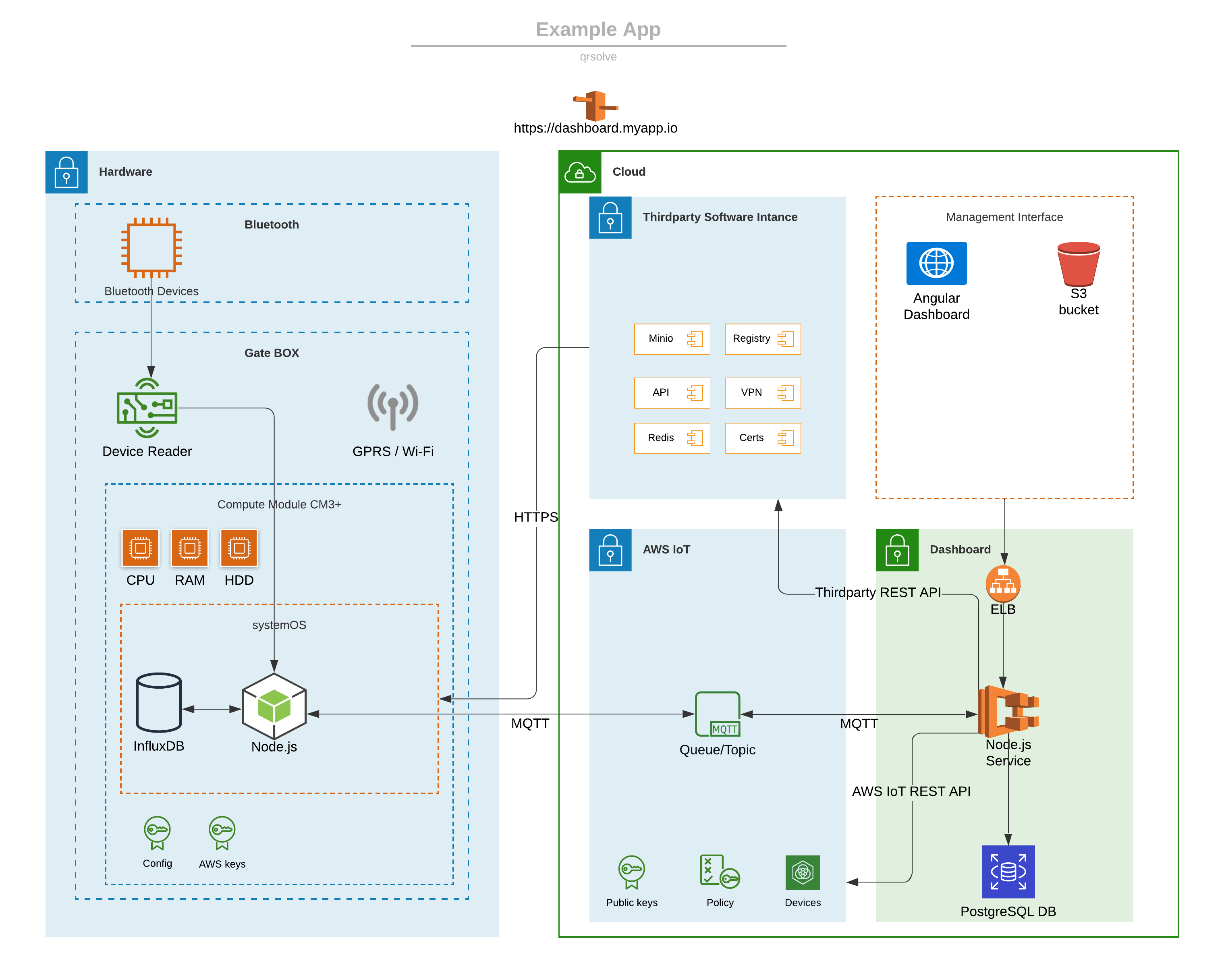

To build a stable and secure environment dedicated to gathering information from thousand of eTags our infrastructure should be well designed and it’s best to be built with a Software as a Service model in the Cloud. We would like to have 24/7 access to view and manage all our connected devices and manage everything using a modern, user-friendly application dedicated to system administrators. Let’s see example of modern IoT system architecture:

Inside of the architecture:

-

24/7 available user dashboard

-

Real-time data synchronization with our hardware equipment

-

eTags management, personalization and status modification

-

Hardware management and monitoring

Of course, our hardware part is the heart of our solution being responsible for integrating and gathering all devices and eTags in real-time to provide complete information about product status positions and availability to operators. This solution can be easily integrated with third-party software via REST API or a message notification system in the future.

Integration

Distributed IoT systems should be well integrated on every architecture level with the highest standards. All parts of the system should be securely connected to provide a safe and fast ecosystem driven by business needs.

-

Provisioning for every new device is completely automated and based on the system process

-

Pairing new products with eTags as the mass process is supported

-

Onboarding into the system is a natural and easy-to-go process

-

Managing of physical products should be focused in one place

Products with eTags are living in a system to be tracked in a completely automated way, thanks to close integration between all physical and logical components.

Summary

Building distributed IoT systems divided between software and hardware part is a challenge because we will probably need cross-functional teams with different competencies from Electronic, Cloud, Development, and integration. If you decide to do this you can be sure of a lot of fun and interesting modern solutions and patterns.

But don’t worry, let’s start building something interesting!

Agile

Agile